-

微切

掌握精度:Microcut® 用于连续精细切割和高效乳化

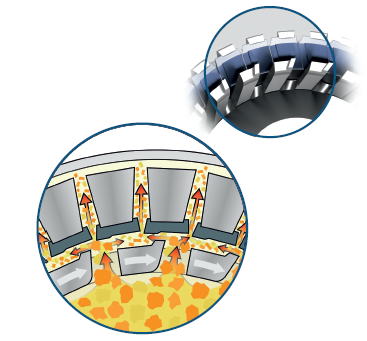

精度和性能:Microcut® 是广泛应用于连续精细切割、高效乳化、分散和均质的终极解决方案。从腌制和酱料制作到水果和蔬菜加工、婴儿食品制备、肉类乳液、肝脏肉酱生产、鱼类产品开发,甚至宠物食品生产,Microcut® 都能提供无与伦比的性能。其耐用的转子定子系统保证了配料的均匀分布,并确保小批量和大批量生产都能达到完美效果。

尖端效率:集成式细毯和乳化技术

由于采用了创新的非接触式转子定子系统,我们可以将顶级的精冲和乳化功能无缝集成到一台机器中。我们先进的低磨损工具无需频繁调整,使用寿命更长。我们的设备产量高,维护和更换时间短。

拥抱剩菜剩饭:利用 Microcut® 技术提高可持续性

优先考虑可持续发展对环境和经济福祉都至关重要。Microcut® 彻底改变了这一理念,无需丢弃返工或半成品。现在,这些剩料可以无缝地融入配料中,从而改进烘焙食品或巧克力生产等工艺。结果如何?降低成本,减少食物浪费,减少二氧化碳排放量。

为每项任务提供合适的加工解决方案

-

MICROCUT® CLASSICFor low and medium viscous products

- Capacities up to 6,000 kg/hour

- Feeding via hopper

- Outlet via pipe (pumpable)

- Main applications:

- Emulsions

- Marinades and sauces

- Fruit and vegetable products

- Confectionery and baked goods

- Liquid products

- Chunky food products

- Nuts

-

MICROCUT® INLINEFor continuous processes and low to medium viscous products

- Capacities up to 6,000 kg/hour

- Feeding via hopper

- Outlet via pipe (pumpable)

- Main applications:

- Emulsions

- Sweets and baked goods

- Dressings, sauces

- Mayonnaise, ketchup

- Liquid products

- Pureed foods

-

MICROCUT® FS LOWFor high-viscosity products that are pumped after cutting

- Capacities up to 4,500 kg/hour

- Feeding via hopper with

screw conveyor - Outlet via pipe (pumpable)

- Main applications:

- Cutting fruits and vegetables

- Medium- to high-viscosity sausage meat

- Chunky food products

- Confectionery

-

MICROCUT® FS HIGHFor grinding dry or frozen ingredients

- Capacities up to 4,500 kg/hour

- Feeding via hopper with

screw conveyor - Outlet via chute, into a container

or onto a conveyor belt - Main applications:

- Cutting fruits and vegetables

- Cutting nuts

- Rework

- Pureed foods

- Baked goods

下载我们的手册,了解更多信息。

食品应用联系人:

Eckhard Hellwig

+49 171 4808785

日化、医药、化工应用联系人:

Thomas Arnegger

+49 160 913 40 768