-

MICROCUT

Mastering Precision: The Microcut® for Continuous Fine cutting and Efficient Emulsifying

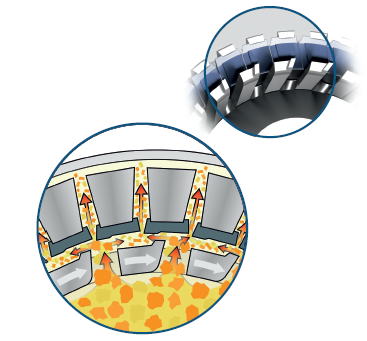

Precision and performance: The Microcut® is the ultimate solution for continuous fine cutting and efficient emulsifying, dispersing and homogenizing in a wide range of applications. From marinating and sauce making to fruit and vegetable processing, baby food preparation, meat emulsions, liver pâté production, fish product development and even pet food production, the Microcut® offers unparalleled performance. Its durable rotor stator system guarantees even distribution of ingredients and ensures perfection for small and large batches.

Cutting-Edge Efficiency: Integrated Fineblanking and Emulsifying Technology

Experience top-tier fineblanking and emulsifying capabilities seamlessly integrated into one machine, thanks to our innovative non-contact rotor stator system. Our cutting-edge, low-wear tools eliminate the need for frequent readjustments and boast an extended service life. Benefit from high throughput rates with minimal maintenance and changeover times.

Embracing Leftovers: Enhancing Sustainability with Microcut® Technology

Prioritizing sustainable practices is crucial for both environmental and economic well-being. Microcut® revolutionizes this concept by eliminating the need to discard reworked or semi-finished products. These leftovers can now be seamlessly integrated into ingredients, enhancing processes such as baked goods or chocolate production. The outcome? Reduced costs, minimized food waste, and a diminished CO2 footprint.

The right processing solution for every task

-

Microcut CLASSICFor low and medium viscous products

- Capacities up to 6,000 kg/hour

- Feeding via hopper

- Outlet via pipe (pumpable)

- Main applications:

- Emulsions

- Marinades and sauces

- Fruit and vegetable products

- Confectionery and baked goods

- Liquid products

- Chunky food products

- Nuts

-

Microcut INLINEFor continuous processes and low to medium viscous products

- Capacities up to 6,000 kg/hour

- Feeding via hopper

- Outlet via pipe (pumpable)

- Main applications:

- Emulsions

- Sweets and baked goods

- Dressings, sauces

- Mayonnaise, ketchup

- Liquid products

- Pureed foods

-

Microcut FS LOWFor high-viscosity products that are pumped after cutting

- Capacities up to 4,500 kg/hour

- Feeding via hopper with

screw conveyor - Outlet via pipe (pumpable)

- Main applications:

- Cutting fruits and vegetables

- Medium- to high-viscosity sausage meat

- Chunky food products

- Confectionery

-

Microcut FS HIGHFor grinding dry or frozen ingredients

- Capacities up to 4,500 kg/hour

- Feeding via hopper with

screw conveyor - Outlet via chute, into a container

or onto a conveyor belt - Main applications:

- Cutting fruits and vegetables

- Cutting nuts

- Rework

- Pureed foods

- Baked goods

Download our brochure to learn more.