Gentle processing for optimum texture and taste

-

LET’S MAKE

Hummus &

tahini

Innovative solutions for your hummus production

ProXES offers you customized and efficient technologies that cover all aspects of hummus production - from chickpea processing to the filling of the end product.

Our integrated systems guarantee the highest product quality and maximum efficiency, enabling you to achieve your production goals quickly and sustainably.

20% of the global B2B hummus production volume is produced with ProXES systems

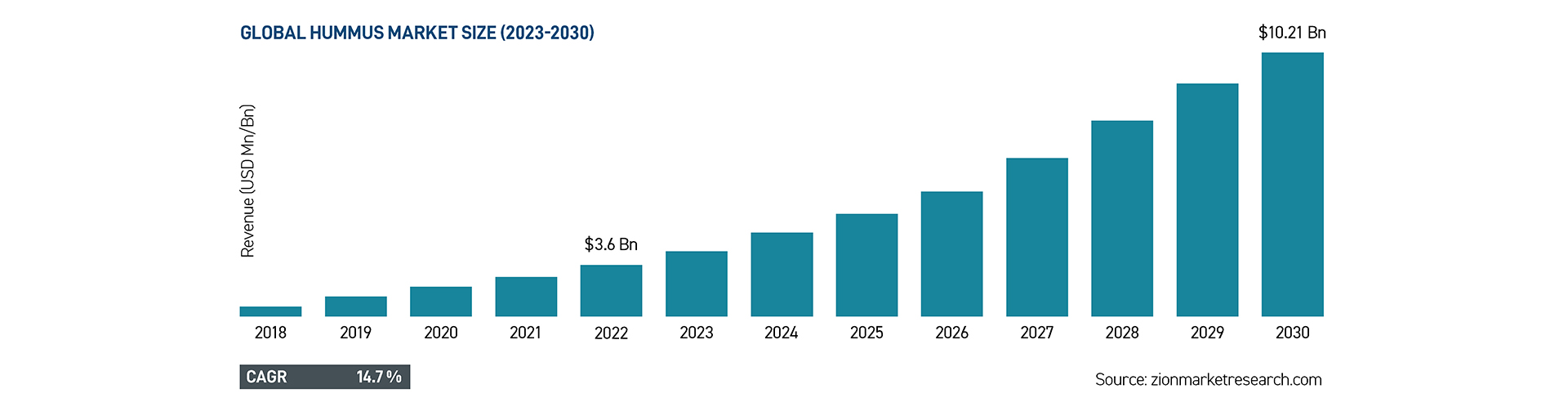

Hummus is no longer just a niche product for food enthusiasts - the global hummus market is steadily growing and shows no signs of slowing down. Driven by trends such as plant-based diets and healthy snacking, the market is expected to reach a value of over USD 10.21 billion by 2030. This presents a significant opportunity for businesses that are ready to capitalize on this trend.

With ProXES processing systems, you can fully harness this growth potential. Our advanced technologies allow you to efficiently expand your production capacities, whether you’re producing small batches or large quantities.

(Zion Market Research. (2022). Hummus market by product type (traditional hummus, flavored hummus), by distribution channel (online, offline), and by region: Global industry perspective, comprehensive analysis, and forecast, 2022 – 2028. Zion Market Research. www.zionmarketresearch.com/report/hummus-market)

HUMMUS PRODUCTION MEETS YOUR REQUIREMENTS

With ProXES, you have full flexibility to adapt your hummus production exactly to your requirements – whether through hot or cold processes, or even by integrating pre-cooking stages.

Our state-of-the-art systems support a variety of production methods, including precise temperature control for optimal blending of ingredients, efficient cooking processes, and seamless integration of pre-cooking or soaking of chickpeas. Whether you’re working with traditional recipes, developing new formulations, or need to meet specific regulations, ProXES provides the tools to ensure consistent texture, flavor, and quality.

Together, we’ll optimize your entire production chain, from raw ingredient preparation to final product, guaranteeing the best solution tailored to your specific needs and market demands.

Different Hummus flavors? No problem!

The hummus market is constantly evolving and the demand for new, innovative flavors is constantly growing. With the flexible processing systems from ProXES, there are no limits to creativity.

From classic recipes to exotic variations, our technologies help you to produce new flavors efficiently and to the highest quality. Best of all, you can often do all this on the same machines, without any additional investment. This allows you to remain flexible and respond quickly to new market trends.

New Hummus ideas? We accompany you with our customized co-creation solutions!

Take your hummus production to the next level with ProXES' customized co-creation solutions. In our state-of-the-art Technology Centers, we work closely with you to turn your ideas into reality. From initial concept development to final production, we offer you the opportunity to optimize your recipes and processes and adapt them exactly to your needs. Discover how our co-creation solutions can make your company more innovative and competitive.

Optimal hummus production systems for every challenge

Whether small batches or large production quantities - ProXES has the perfect solution for every requirement. Our hummus production systems are flexible and adaptable, allowing you to expand your capacities at any time.

With proven systems such as the Combitherm or the Vacutherm, we guarantee maximum efficiency and product quality. From traditional to innovative recipes, our systems offer you the flexibility and reliability you need.

-

Universal machinesIdeal for the production of small to medium batches

- Versatile and adaptable to different recipes and production volumes

- Efficient manufacturing with options for direct or indirect heating and cooling

- Ensures high quality and consistent results with minimal waste.

-

CombithermDeveloped for large-scale production

- Versatile system that can handle various processing steps

- High capacity, suitable for large production quantities

- Ensures optimum product quality through precise temperature contro

-

VacuthermDeveloped for large-scale production with the finest homogenization

- Combines efficient cooking and cooling processes

- With direct steam injection for fast and gentle heating

- Provides consistent product quality and extended shelf life.

-

Micro CutPerfect for finest homogenization

- Ensures a smooth and uniform texture, which is crucial for high-quality hummus

- Multifunktional, bewältigt sowohl Feinzerkleinerung als auch Dispersion

- Multifunctional, handles both fine grinding and dispersion

- Compact design that can be easily integrated into existing production lines

-

Cook-ItSpecialized in cooking from medium to large batches

- Efficiently handles the initial cooking of chickpeas for hummus

- Supports both hot and cold processing methods.

- Compact and energy efficient, designed for flexibility in production.

JOYN OUR SEMINARS

November 12 + 13

in Hamelin, Germany

In our upcoming seminars, you will gain exclusive insights into the latest trends and technologies in hummus production. Our experts will show you how to further optimize your production processes and develop innovative recipes.

Take advantage of this opportunity to expand your skills and deepen your knowledge.

High-performance hummus lines for large production volumes

ProXES offers customized solutions for large-scale industrial hummus production. Our comprehensive hummus production lines are designed for high production volumes and combine efficiency with the highest product quality.

With our innovative systems such as the Combitherm and Vacutherm, we are setting new standards in industrial food production. Benefit from our turnkey solutions that are precisely tailored to the needs of large manufacturers and maximize productivity.

Just one example: ProXES supplied two systems with an impressive total capacity of 2.3 tons of hummus per hour to a well-known food manufacturer in Saudi Arabia.

Still not convinced? Do it like our partner

At ProXES, every customer trial is a collaboration. We work hand-in-hand with our clients to find the perfect solution that meets their needs and exceeds expectations. One of our long-standing partners, a major player in the food industry, is a prime example of this approach.

For over 20 years, we've been their trusted supplier, mainly for various types of processed cheese. In 2019, we saw an opportunity to take our partnership to the next level. After introducing our hummus production solutions to them and conducting trials at our Technology Center in Hamelin, the results spoke for themselves.

From Cheese to Hummus – A Journey of Innovation

In just three months, the quality and efficiency of our machines was convincing enough to start our first hummus production line together. Today, our client is expanding their capacities and planning a move to a larger facility, where even more production lines will be integrated.

BEHIND EVERY GOOD HUMMUS IS A GREAT TAHINI

From Sesame to Tahini: ProXES Ensures Excellence in Every Step of Your Production

ProXES offers you customized solutions for the production of high-quality tahini. Our technologies guarantee gentle manufacturing that ensures an optimal texture and excellent taste. From sesame preparation to fine grinding, our systems ensure that every detail of your production is perfected. With ProXES, you not only ensure first-class product quality, but also efficient and sustainable production processes.

Download our latest brochure to learn more.

CONTACT US!

Do you have any questions or need support with your hummus or tahini production? Our team of experts is on hand to provide you with customized solutions tailored to your exact needs. Contact us today to find out how we can work together to achieve your production goals.

NEED TO KNOW MORE? GET IN TOUCH WITH OUR EXPERTS.

食品应用联系人:

Eckhard Hellwig

+49 171 4808785