-

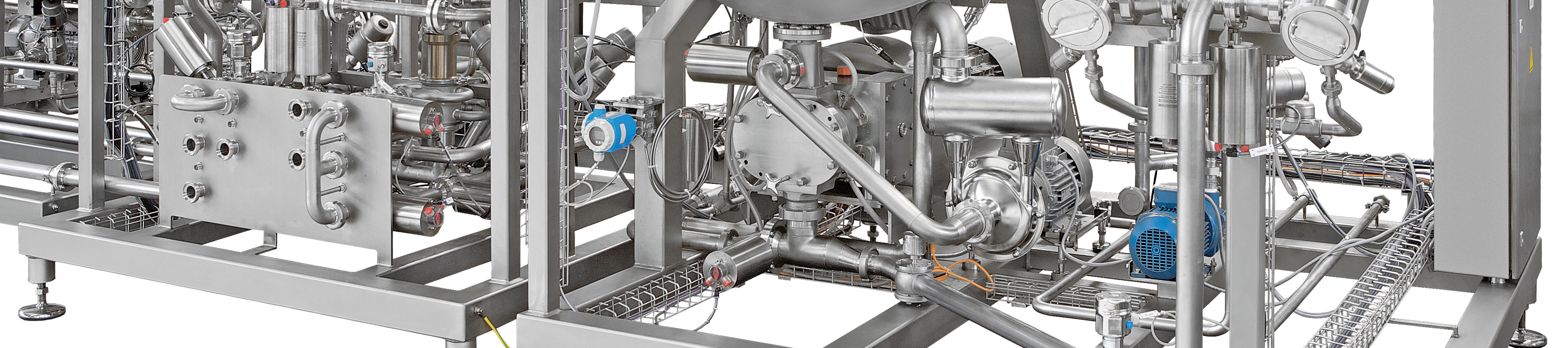

Vacuum cooling

& Evaporating

In a vacuum, water boils and evaporates at much lower temperatures than at normal atmospheric pressure. This phenomenon is used in food processing both for fast, energy-efficient cooling and for concentrating products.

By combining a vacuum pump and heat exchanger, the boiling point of the product is lowered - the water in the product evaporates at reduced pressure. The energy required for the liquid-gas phase transition is extracted from the food. The result is a rapid drop in temperature. Foods such as marzipan, processed cheese, baby food or fruit preparations can be cooled down to the desired filling temperature within a very short time while retaining natural flavors and colors.

Evaporation is a gentle method of dehumidification of products. The boiling point of water is lowered, e.g. at temperatures of 60°C (corresponds to a high vacuum of 80 %) to remove the water from the product. The concentration of the products at low temperatures and high vacuum enables the preservation of heat-sensitive nutrients and volatile flavors.

Our experts for vacuum cooling and evaporating including condensing units:

UHT Systems

Continuous ultra-high temperature

COOK-IT®

Compact batch cooking solution

Vacutherm

Efficient hot & cold processing

Universal Machine 200

Perfect for small & medium batches