-

UHT

SYSTEM

Modular UHT-System: Revolutionizing Continuous Processed Cheese Production

The popularity of processed cheese creations of all kinds is growing continuously. Our modular UHT system offers a perfectly coordinated solution for the continuous production of sliceable or spreadable processed cheese preparations. Reliable ultra-high heating, cooling and creaming of food on an industrial scale minimizes the use of preservatives and eliminates the need for a continuous cold chain from production to the end customer. The UHT system consists of two core components - the UHT module and the flashcreaming module - and can be expanded as required to create a customized production environment for any process.

Two modules for maximum efficiency

UHT Module

In the UHT module, ultra-high temperature treatment is carried out using direct steam injection. Culinary steam is injected directly into the product. All the necessary production parameters, such as the temperature, are precisely controlled and monitored by the automation system. The steam heats the product in the UHT head quickly and efficiently from approx. 85 °C to 142 to max. 145 °C. Unwanted deposits or scorching are reliably prevented by the PTFE coating.

In the hot holding section, the product is kept under pressure for the duration of the sterilization process. In the event of unexpected temperature fluctuations, a changeover valve automatically ejects the product and thus ensures that only perfectly heat-treated preparations enter the vacuum cooling and creaming module.

The UHT module has two heads which, in combination with an external CIP unit, enable virtually uninterrupted operation. While one head is being cleaned, production can continue without interruption.

FC Module

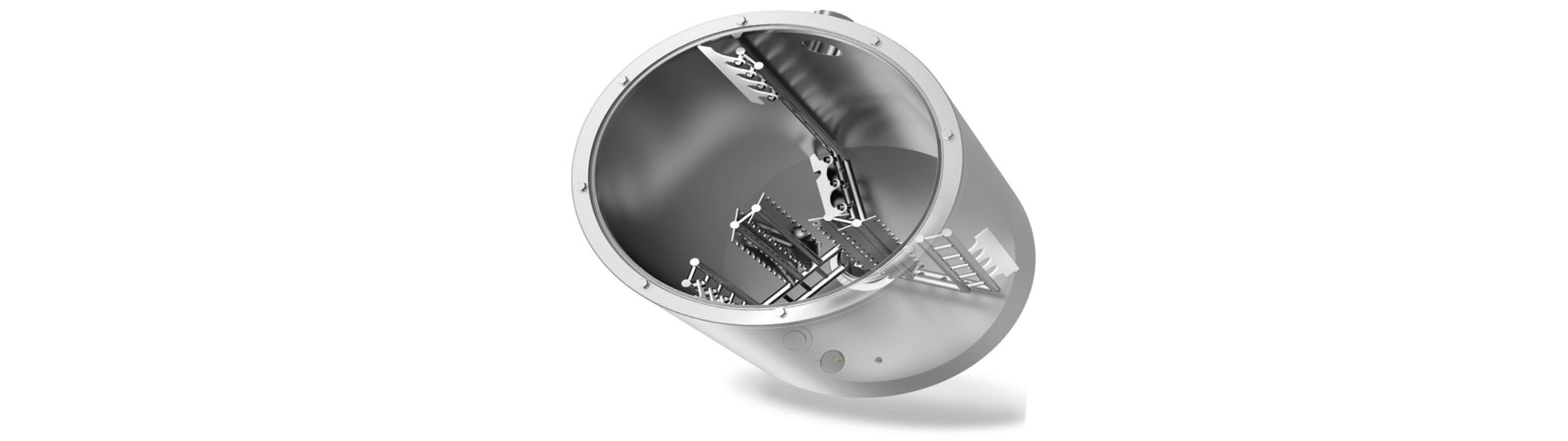

The Stephan FC module combines flash cooling and creaming in one vessel. A vacuum is created in this vessel, which quickly vaporizes the water content of the hot product and thus releases a lot of energy. The amount of water evaporated corresponds to the amount of steam added during UHT heating. A vacuum pump transports the resulting hot vapor from the container into a condenser, where the water is collected.

In order to separate gas and liquid more efficiently, the product is fed into the tank as a falling film without touching the tank wall. The vacuum can be precisely adjusted to achieve the ideal temperature for creaming (around 86-88 °C). This rapid cooling prevents unwanted reactions and burns. The vacuum and falling film also help to remove air from the product, ensuring high quality and accurate filling.

Enhancing product texture

Ultra-high heating affects the internal structure of the product. To be able to fill it, the lost viscosity and creamy texture must be restored. A special agitator and the inclined position of the container allow particularly shear-intensive stirring. The continuously adjustable speed of the agitator offers flexibility with regard to the desired product consistency. The temperature and product volume in the creaming container also influence the texture of the fillable end product and can be precisely controlled.

Your benefits with our UHT systems

-

MODULAR AND COMPACT

Modular system with a small footprint

-

CUSTOMISED PRODUCT QUALITY

Customised product quality in colour, gloss and texture

-

AUTOMATED CLEANING

High process availability due to automated cleaning (CIP)

-

OPERATOR FRIENDLY

Intelligent and intuitive handling

-

CONTINUOUS OPERATION

Highly efficient process control for continuous operation

-

ULTRA-HIGH HEATING PROCESS

Fast, efficient yet gentle direct-steam heating

Download our brochure to learn more.